WEEDS: ERADICATING NOTHING BUT DOING SOMETHING

Updated September 23,2003

1st Presented at San Francisco ('99)/

Palm Springs (2000) IECA and SERR.M. Dixon

The no-till method for seeding called land imprinting has been under development in Tucson , Arizona since 1976. Ranchers have applied imprinting to restoring perennial grasses on their degraded rangeland for erosion control and forage production. Since 1980 some 20,000 hectares have been interseeded with grasses in southern Arizona . Early imprinters were massive machines with large diameter rollers that were designed to operate on rocky, brushy terrain of the southwestern deserts. Imprinters are now being designed for ecological restoration and the establishment of cover crops. They have smaller diameter rollers and are easier to transport. Some can work on 2:1 slopes and even steeper. Simple seeders, directly driven from the imprinting roller, can deliver complex mixes of native seeds to the roller top where they are carried forward, dropped on the soil surface and then imbedded in the imprint surfaces. V-shaped imprints funnel resources downward where they can work in concert to germinate seeds and establish seedlings.

Based on more than 2 decades of field experience, land imprinting specifications have been developed for ecological restoration and sustainable agriculture. These include general imprinter and seeder design specifications that will help to insure success of revegetation projects. Also experienced fabricators can use these specifications as a guide for constructing state-of-the-art seeding imprinters.

INTRODUCTION

The science and technology of sustainable agriculture and ecological restoration are merging into a single discipline with the passage of time. Agronomists are applying some ecology and ecologists are applying agronomy in their sustainable agriculture and ecological restoration projects. This merger of the two disciplines is being driven by a common concern over global land degradation or desertification that threatens the welfare and even survival of all species, including our own (Lowdermilk, 1935; Dregne, 1978; Wolf, 1987). While world population of humans is growing rapidly, the acreage of productive land is shrinking making probable shortages of food and medicine in the not too distant future. Agricultural lands are becoming degraded or desertified and are thus less able to provide sustained production of food, feed, and fiber, while becoming an increasing source of environmental pollution. Likewise natural lands are becoming degraded and are thus less able to provide the services of healthy ecosystems such as clean soil, water and air, pollination and abundant and diverse medicinal plants (Buckman and Nabhan, 1996; Chevallier, 1996; Daily, 1997; Duke, 1998).

Land degradation or desertification is caused by such human activities as livestock grazing, forest and woodland logging, land tillage, outdoor recreation, urban and industrial development, and military activities. The foregoing activities cause well vegetated land to become denuded, thereby decreasing rainwater infiltration and increasing water runoff, erosion, sedimentation and flash flooding (Dixon, 1995; Dixon and Carr, 1997). The degraded land is less able to infiltrate and hold soil moisture; consequently, plants experience a more arid environment, especially during short term droughts. A vicious cycle of land aridification and denudation forms the insidious process called desertification, wherein the land dries out and many life forms die or flee (Dregne, 1978).

Both sustainable agriculture and ecological restoration are directed toward ecosystem improvement through management. Management, in turn, seeks to create an ecosystem that is not only productive but also sustainable (maintainable) with lower inputs of labor, fertilizer, pesticides, and tillage (Gliessman, 1998). This best of two worlds is accomplished by creating functional ecosystems using natural systems as models. Natural forest, savanna and prairie ecosystems have stood the test of time, being sustainable through many millennia. Natural soil fertility is provided by organic matter and symbiotic bacteria and fungi, pests are controlled biologically, and tillage is minimized by using no-till practices (St. John, 1998; St. John et al., 1997).

Both sustainable agriculture and ecological restoration are achieved through applied ecology (Gliessman, 1998). When land is disturbed by human action(s) that strip vegetation from the land surface, a secondary succession of plant types ensues, usually beginning with mostly short-lived annuals and ending with mostly long-lived perennials. The speed and direction of this secondary succession can be controlled by management to achieve desired results; however the process occurs naturally, but often quite slowly taking decades, centuries and even millennia depending on the degree of land disturbance, soil type and climate.

In many cases, the goal of sustainable land management is to accelerate the secondary succession toward a productive and sustainable ecosystem. Land imprinting was developed for that purpose ( Dixon , 1980). Imprinters impress seedbeds and seedling cradles that become moist enough to germinate and establish the seeds of perennial species even in severely degraded soils. The smooth walled and V-shaped imprints funnel resources (seed, spores, water, soil and plant litter) downward together where they can work in concert to germinate seeds and establish seedlings (Dixon, 1995; St. John et al., 1997). With imprints, infiltration is rapid and moisture penetration is deep providing the moisture required to germinate and establish the seeds and seedlings of perennial species. Without imprints, infiltration is slow and moisture penetration is shallow, conditions favoring the establishment of annual but not perennial species.

Seeding imprinters have been used to establish perennial grasses in the severely overgrazed rangeland of the desert southwest for ecosystem enhancement, erosion control and greater forage production for livestock and wildlife (Dixon & Carr, 1998). These improved ecosystems will be sustainable if livestock grazing and other human activities are adequately controlled (Belsky et al., 1999; Savory 1988) Such imprinting projects combine the goals of both ecological restoration and sustainable agriculture.

General Specifications

Land imprinting is an application of infiltration control research conducted by the senior author and several coworkers ( Dixon , 1995). Thus, the imprinting roller is designed to impress into the soil surface a geometric configuration for controlling rainwater infiltration to, in turn, restore vegetation on desertified/degraded land areas. Rates, volumes and locations of infiltration are controlled through the process of land imprinting without soil surface inversion and covering of plant litter and with minimal harm to existing vegetation. Rates, durations and volumes of water infiltration are all increased during and shortly after major rainfall events. First-hour rates and volumes are often increased by a factor of ten or more. Infiltration control is at the microscale level of 30-cm (one-foot) square-an areal scale appropriate for revegetation of degraded lands. Most infiltration occurs in the bottom of the imprint trough where the resultant deep soil moisture penetration favors establishment of perennial vegetation.

During the past two decades, the general specifications for land imprinters were derived from the principles of soil mechanics and the hydrobiotic function of soil imprints. Mechanically, imprints are formed through downward acting forces applied to angular steel teeth. Troughs or indentations are formed through soil compression and shearing, whereas adjacent crests or ridges are formed by an embossing (lifting) process. Thus, the original soil surface lies in a plane about midway between the imprint trough and crest. A 5-cm (two-inch) gap around each tooth facilitates these two interacting processes with minimal soil disturbance and compaction.

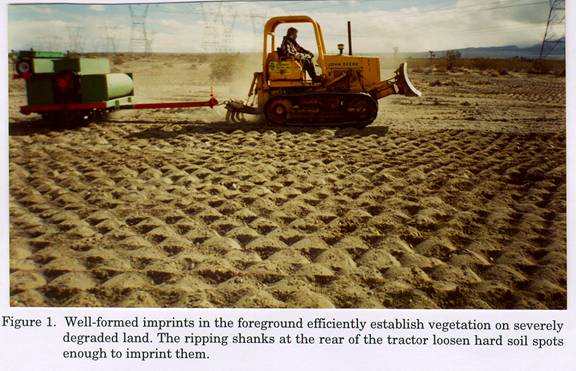

Imprints are 25-cm (10-inch) long, V-shaped troughs or microwatersheds which funnel resources to the bottom of the vee where they can work in concert to germinate seeds and establish seedlings. Each microwatershed is about 30-cm (one-foot) square in surface area and can hold several liters of rainwater on level ground. This is enough water to germinate and establish one or more seeds or seedlings. Imprints are staggered and separated by 5-cm (two-inch) wide dikes at the soil surface for safe storage of rainwater until it infiltrates. The staggering also gives plants more room to develop and better exposure to vital resources including water and light. Imprints that satisfy the general specifications are pictured in figure 1. Such imprints will almost always lead to successful revegetation if the seed mix is adequate. Such imprints are stable enough to wait several years for adequate rain to occur in the desert.

Imprints that fail to satisfy the general specifications often result in thin and uneven stands of vegetation. Poor design features and their consequences include:

(1) Imprints that are greater than 25 cm (10-inches) long can lead to rill and gully formation.

(2) Imprints that are too widely spaced produce thin stands and cannot store enough rainwater to control water runoff and erosion.

(3) Imprints that are too shallow because of insufficient imprinter ballast do not hold enough water for seed germination and runoff and erosion prevention.

(4) Imprinting roller cores that are too small, diameters less than 50 cm (20 inches), tend to round the crests of imprints due to excessive sliding and shearing actions. This rounding results in excessive tillage, weed seed germination, covering of existing plant litter, and damage to existing vegetation.

Imprint size, shape, spacing, and pattern are designed to maximize resource funneling and the safe temporary storage of rainwater. On level ground, each imprint can hold 3 to 5 liters of water, which is equivalent to 5 to 9 surface cm (2 to 3.5 inches). Imprints are V-shaped troughs, the sides of which funnel rainwater and seed to the line at the trough bottom where sufficient water concentration and infiltration occur to effect seed germination and seedling establishment. The bottom of the trough typically forms a shrinkage crack on drying, thereby eliminating the crusting-emergence problem often associated with fine-textured soils. After germination and emergence, the sides of the trough humidify the microclimate and shield young seedlings from excessive sunlight and dry winds ( Dixon , 1995).

The preceding functions of imprints result in much better stands of seedlings, faster growth rates, and higher survival-all relative to various types of drill seeders including no-till. The relative benefits of imprinting increase as slope steepness increases and annual precipitation decreases.

Roller Categories

To assist readers who wish to make their own imprinters, specifications are given in U.S. Customary (English) units. The structural steel used to fabricate imprinters is available in these units. Conversion factors are given for the convenience of those working in countries where steel has metric dimensions.

Six categories of imprinting rollers result from various combinations of 2 angle sizes (6"x 6" & 8" x 8"), 2 angle shapes (straight and bowlegged) and two cylindrical core diameters (20" & 24"). Category specifications are given in the table below. Angular teeth are welded radially around the core to form 6 or 8 pointed star rings. Tooth length is 10 inches and the spacing between rings is about 2 inches. Thus, there is one star ring for each 12 inches of imprinting roller length. Points on adjacent star rings are staggered to suppress gully formation. The radial basal spacing of imprinting teeth is also about 2 inches. This 2-inch gap around the base of each tooth improves penetration into the soil while providing a dam between adjacent imprints for safe storage of collected rain or irrigation water until it infiltrates. All six categories of imprinting rollers make imprints or microwatersheds about 12 inches square in size and shape. These small isolated watersheds provide excellent control of infiltration and the microclimate, thereby greatly accelerating revegetation processes. A sample imprinting roller is pictured in Figure 2.

Table 1. Imprinter Roller Dimensions In Inches

Roller Cylindrical Core Angular Teeth Legs Teeth per Category D C Length(L) Width(W) Star

I 20 62.8 6 8.5 6 II 20 62.8 6 6.0 8 III 20 62.8 8 8.0 6 IV 24 75.4 6 8.5 8 V 24 75.4 8 11.3 6 VI 24 75.4 8 8.0 8 Footnotes: D = Diameter & C = Circumference, 1" = 1 inch = 2.54 cm, 1 foot @ 30 cm, sketches for Table 1 follow:

Figure 2. Category II, 7-foot imprinting roller designed for revegetating steep slopes.Tow Frame

The front and rear of the tow frame are square tool bars which permit the use of commercial tool clamps for easy attachment of hitches and accessories (Figures 3 & 4). Typically the drawbar tongue is removed for trailer hauling to reduce the width of the load. Since the front and rear of the tow frame are identical, hitches can be attached to either side to reverse the direction of roller rotation. This feature nearly doubles the life of imprinting teeth, the tips of which concave sharpen on their leading edges.

Frame Shape and Size: Rectangular to fit rollers 3,4,5,6,7,8,9 & 10 feet in length

Frame Front & Rear: Square tool bar (2 ¼-inch side)

Frame Ends: Clamped to tool bars with center bearing bracket

Roller Axle: Full-length, cold-rolled steel, 2 ½-inch diameter

Axle Bearings: Pillow block type with cast steel housing and double tapered roller bearings

for 2 ½-inch axle

Tool Bar Attachments:

(1) Drawbar tongue for field operation

(2) Trailer loading and unloading wheels

(3) Three-point hitch (optional)

(4) Ripping shanks (optional)

Figure 3. Imprinter tow frame with imprinting roller and loading/unloading wheels attached.

Figure 4. Imprinter tow frame attached to a dozer blade to form a

steep-slope imprinter. Tractor hydraulics force imprinting teeth into the ground.

Seeder Specifications

The seeder is designed for the selected roller category. Active agitation keeps the seed well mixed while uniformly discharging a controlled amount of seed to the top of the imprinting roller where it is carried forward and imbedded in the surface of the newly formed imprints. Successive rains then move seeds from the upper reaches of the imprinted microwatersheds into the bottom of imprints where moisture conditions favor seed germination and seedling establishment. This process extends the time window of opportunity for successful stand establishment.

Morphologically diverse mixtures of seeds can be uniformly discharged through time by mixing the seeds with wheat bran--an inexpensive by-product of white flour milling. Flaky wheat bran prevents the fluffy, low density seeds from migrating upward and the smooth, high density seeds from moving downward to ensure a vertically uniform seed mix.

Seedbox Shape: Semicircular bottom with vertical sides ( See sketch ).

Seedbox Height: Same as roller core diameter (D).

Seedbox Width: Same as seedbox height or D.

Seedbox Length: Same as roller core length.

Seed Agitator: Rotating vane type with 4 flexible blades.

Agitator Drive: Rubber tire in frictional contact with imprinting tooth ring.

Seed Discharge: Via one-inch circular holes (one per tooth ring) with discharge rate controlled by a sliding gate with holes matching those in the bottom of the seedbox.

Imprinting Force

Land imprinting obeys the balance of force equation:

Downward Acting Force = Upward Acting Force

or

Imprinting Force or Pressure = Soil Load Bearing Capacity

Thus, an imprinting roller will penetrate or settle into the soil to the depth where the opposing forces are equal or balanced. For a full-tooth imprint, these forces balance when the teeth penetrate the soil halfway, because of the embossing effect. When soil load bearing capacity is too high or the soil is too hard for halfway penetration of the imprinting teeth, additional weight can be loaded onto the imprinter or the soil can be softened by ripping or wetting. Usually the best alternative is to add more weight up to a static imprinting pressure of about 207 KPa (30 pounds per square inch, psi).

Imprinters are designed to have an adjustable range of static imprinting pressures of 104 to 207 KPa (15 to 30 psi). For the 2.43-meter (8-foot) imprinter with straight angles, the base 1816 kg (2-ton) weight gives an imprinting pressure of about 104 KPa (15 psi). Loading the imprinter with an additional 1816 kg (2 tons) raises the imprinting pressure to about 207 KPa (30 psi). Thus, as a rule of thumb, the static imprinting force per 30 cm (foot) of roller length should range from 227 kg (500 pounds) when the imprinter is unloaded to 454 kg (1000 pounds) with a full load. Imprinter loading is accomplished by filling the imprinting roller core with water and by mounting water tanks or soil boxes on the imprinter frame. Tanks or boxes are mounted on both sides of the seedbox such that the weight is balanced over the axle of the imprinting roller. Tanks are the same size as the imprinting roller core, whereas soil boxes are about the size of the seedbox. The outer side of soil boxes should be removable to expedite emptying of the well settled soil. The imprinting tow frame (Figure 3) can be loaded using the tractor's hydraulic system and 3- or 4-point hitches or by soil boxes attached to the tool bar frame. The hydraulic system that operates the dozer blade is used to load the steep-slope imprinter shown in Figure 4.

Tillage, before imprinting, kills existing vegetation, covers plant litter, breaks down soil structure, and encourages weed growth. Thus, tillage should be avoided as an alternative to adding weight to the imprinter frame. However, if tillage is required because of deep soil compaction, ripping is less destructive than disking. Also, mycorrhizal inoculum can be injected several inches deep behind the ripping shanks. Another alternative to ripping hard soils, is to imprint them twice. For instance, if the first imprinting is only one-half of the full depth, the second one will be markedly deeper because imprinting teeth tend to get in gear with the first imprints and then bite deeper into the soil.

The static pressures of 104 and 207 KPa (15 and 30 psi) are based on the soil contact area resulting from the halfway penetration of 6 teeth for the 240 cm (8-foot) imprinter. The general formula for the number of teeth in contact with the soil is 1.5 times the number of in-line teeth or 0.75 times the length of the imprinting roller in feet. The quantitative soil mechanics of land imprinting is extraordinarily complex and poorly understood. Thus, the analysis presented here is only a greatly simplified first approximation.

Finally, it should be noted that the actual or dynamic imprinting pressures are much greater than the static pressures. Soils with a hardness of 690 KPa (100 psi), as measured with a cone penetrometer, can be imprinted by an imprinter producing a static pressure of 207 KPa (30 psi). Thus the momentum of the revolving imprinting roller apparently increases imprinting force by more than 3 times. Just as stepping lightly on soft soil leaves no footprints, stamping, running and jumping does. Another explanation is that the imprinted soil weakens the adjacent unimprinted soil, thereby lowering the imprinting force required as the imprinter rolls along.

Under field conditions, soils usually vary greatly in hardness from point to point with some areas requiring ripping and some not. A tractor equipped with a ripping tool bar and a drawbar for towing the imprinter allows the operator to selectively rip only the hard spots while imprinting the whole area as shown in Figue 1.

SUMMARY

The following points and notes serve to briefly summarize the specifications for seeding imprinters.

1. Imprint geometric shape: V-shaped trough.

2 . Imprint top shape: Rectangular almost square.

3. Imprint top area: About one square foot.

4. Imprint length: 10 inches.

5. Imprint top width: 6 to 12 inches.

6. Imprint end spacing: 2 to 3 inches.

7. Imprint side top spacing: 2 to 3 inches.

8. Imprint depth: 4 to 7 inches.

9. Imprint pattern: staggered (Fig. 5).

10. Imprinter teeth: Ten-inch lengths square cut from 6"x6" or 8"x8" steel angle.

11. Imprinting roller length: 3 feet up to a 10-foot maximum in one-foot increments.

12. Roller core diameter: 20-inch minimum.

13. Imprinting pressure: Adjustable from 15 to 30 pounds per square inch (psi).

14. Seeder Design: Seed agitating and discharge mechanism uniformly distributes trashy or fluffy seed mixes of native species just in front of the imprinting roller at the prescribed rate per acre.

Notes

a. See Table 1 for the six categories of imprinting rollers which satisfy the first twelve specifications, listed above.

b. Land imprinter should be loaded enough to produce full-tooth imprints. Deeply compacted soils should be ripped before imprinting.

c. Imprinter seed sometime during the fall months preferably following the first good rain but before the ground freezes.

d. Native seed mixes for ecological restoration should include early, mid and late successional species with at least one-fourth by weight being the seeds of early seral or pioneer species. Also include a cool season annual to provide quick cover for erosion control.

e. Conversion factors: 1 inch = 2.54 cm, 1 foot = 30 cm, 1 psi = 6.90 KPa

Figure 5. Diagramatic overhead view of one-foot square imprints. Arrows pointing to

narrow line signifies resource funneling into imprint trough. Broad lines represent dikes

that separate adjacent imprints. Pattern shown represents about one revolution

of a standard 6-foot imprinting roller. Scale: 1 inch = 1 foot .REFERENCES

Belsky, A.J., A. Matzke and S. Uselman. 1999. "Survey of Livestock Influences on Stream and Riparian Ecosystems in the Western United States ." J. Soil & Water Cons . 54 (1): 419-431.

Buchman, S.L. and G. P. Nabhan. 1996. The Forgotten Pollinators. Island Press, Covelo , CA 292 pgs.

Chevallier, A. 1996. The Encyclopedia of Medicinal Plants . D.K. Publishing Inc. New York , NY . 336 pgs.

Daily, G.C. 1997. Nature's Services: Societal Dependence on Natural Ecosystems . Island Press, Covelo , CA 392 pgs.

Dixon , R.M. 1980. "Land Imprinter." U.S. Patent No. 4185655. U.S. Patent Office, Washington , D.C.

Dixon , R.M. 1995. "Water Infiltration Control at the Soil Surface: Theory and Practice". J. Soil & Water Cons . 50(5): 450-453.

Dixon , R.M. and A.B. Carr 1997. "Infiltration Regulation for Erosion Control: Principles and Practices". Proc. Conference 28, International Erosion Control Association , February, p. 153-164.

Dixon , R.M. and A.B. Carr 1998. Land Imprinting for Restoring Vegetation in the Desert Southwest. Annual Conference on Ecosystems Restoration and Creation. Hillsborough Community College , Institute of Florida Studies, 14-15 May, Tampa , Florida . IN PRESS.

Dregne,H.E. 1978 "Desertification:Man's Abuse of the Land" J. Soil & Water Cons . 33: 11-14.

Duke, J.A. 1997. The Green Pharmacy . Rodale Press, Inc., Emmaus , PA 617 pgs.

Gliessman, S.R. 1998. Agroecology: Ecological Processes in Sustainable Agriculture . Ann Arbor Press, Chelsea , MI 357 pgs.

Lowdermilk, W.C. 1935. "Man Made Deserts." Pacific Affairs 8(4): 409-419.

Savory, A. 1988. Holistic Resource Management . Island Press, Covelo , CA .

St.John,T. 1998."Mycorrhizal Inoculation in Habitat Restoration". Land & Water .42(5):17-19.

St.John, T., R.M. Dixon and M.St. John. 1997. "Restoring Arizona 's Discovery Park . Hortus West 8(2): 16-17, 56-59 & 107.

Wolf, E.C. 1987. On the Brink of Extinction: Conserving the Diversity of Life . Worldwatch Institute, Paper 78, 54 pgs.

SEEDING IMPRINTERS: SUMMARY OF STANDARD SPECIFICATIONS*

1. Imprint geometric shape: V-shaped trough.

2 . Imprint top shape: Rectangular almost square.

3. Imprint top area: About one square foot.

4. Imprint length: 10 inches.

5. Imprint top width: 6 to 12 inches.

6. Imprint end spacing: 2 to 3 inches.

7. Imprint side top spacing: 2 to 3 inches.

8. Imprint depth: 4 to 7 inches.

9. Imprint pattern: staggered (Fig. 5, Dixon & Carr 2000).

10. Imprinter teeth: Ten-inch lengths square cut from 6"x6" or 8"x8" steel angle.

11. Imprinting roller length: 3 feet up to a 10-foot maximum in one-foot increments.

12. Roller core diameter: 20-inch minimum.

13. Imprinting pressure: Adjustable from 15 to 30 pounds per square inch (psi).

14. Imprinter weight: 500 pounds minimum per foot of imprinting roller length.

15. Imprinter ballast: 500 pounds minimum per foot of imprinting roller length.

16. Seeder Design: Seed agitating and discharge mechanism uniformly distributes trashy or fluffy seed mixes of native species just in front of the imprinting roller at the prescribed rate per acre.

Notes

a. See Table 1(Dixon & Carr, 2000) for the six categories of imprinting rollers which satisfy the first twelve specifications, listed above.

b. Land imprinter should be loaded enough to produce full-tooth imprints. Deeply compacted soils should be ripped before imprinting.

c. Imprinter seed sometime during the fall months preferably following the first good rain but before the ground freezes.

d. Native seed mixes for ecological restoration should include early, mid and late successional species with at least one-fourth by weight being the seeds of early seral or pioneer species. Also include a cool season annual grass to provide quick cover for erosion control.

e. Conversion factors: 1 inch = 2.54 cm, 1 foot = 30 cm, 1 psi = 6.90 Kpa, 1 pound = 453 gm.

* Specifications were published in the year 2000 and updated in 2003. Details may be found in the publication:

Dixon , R.M., and A. B. Carr 2000. Land Imprinting Specifications for Ecological Restoration and Sustainable Agriculture. Proc. Conference 31, International Erosion Control Association. February 21-25, Palm Springs, CA p. 157-169.

The Imprinting Foundation

1616 E. Lind Road

Tucson, AZ 85719Close Window to Return to List

If you entered our site on this page, click on Logo below to go to the Imprinting Foundation for more Information