LAND IMPRINTING FOR LOW-COST REVEGETATION OF DEGRADED LAND

IN THE DESERT SOUTHWEST: UPDATED/EXPANDED VERSIONSeptember 26,2003

Robert M. Dixon, Ph.D and Ann B. Carr

ABSTRACT

This paper traces the research and development of land imprinting since 1976 for low-cost revegetation of degraded land. Rainwater infiltration research ,conducted by the senior author and several coworkers, led directly to the conceptualization of land imprinting. This research, representing a wide range of climatic, edaphic and vegetal conditions, showed that the microroughness and macroporosity of the soil surface control the rates and routes of rainwater infiltration into dry soils. Thus, manipulation of these two properties of the air-earth interface holds the key to wide-range infiltration control. In turn, infiltration control is the key to water erosion control since very high infiltration rates essentially eliminate water runoff and thus water erosion. The soil surface of degraded land is typically smooth and sealed due to the splashing action of raindrops impacting a bare soil surface. Such a surface will infiltrate rainwater only 1 / 10 to 1 /100 as fast as a microrough, macroporous surface. Thus, infiltration control is also the key to revegetation of degraded land. Land imprinting was developed to convert the smooth-sealed surface of degraded land back into the rough-open condition to, in turn, restore high infiltration rates and deep rainwater penetration in the most efficient way possible. Land imprinters are designed to reshape the soil surface to impart roughness and openness with minimal disturbance of plant material and soil structure. Unlike conventional implements, land imprinters do not dig into, loosen, and invert the surface soil, covering plant materials in the process. Instead they impress and emboss smooth-walled, V-shaped furrows in the soil surface, mulching any aboveground plant material that is available. The resulting waffled surface is highly stabile and can rapidly infiltrate rainwater where it falls. A wide variety of imprinting devices has been designed, fabricated and tested under diverse field conditions. Imprinting success depends on a good seed mix, good imprints and adequate rainfall to germinate seeds and establish seedlings. Less rainfall is required for seedling establishment as compared with drilled furrows because of the six important functions of imprinting and imprints--mulching, firming, trapping, funneling, infiltrating, and shielding. As a result of these six functions, land imprinting has been successful in establishing vegetation in the Desert Southwest of the U.S.A. about nine times out of ten as compared with only one in ten for conventional methods such as drilling. During the past decade, tens of thousands of hectares have been revegetating by imprinting in southern Arizona alone. Most of the land that was imprinted had been degraded by cattle grazing, however some had been disturbed by urban and industrial development

INTRODUCTION

Vast areas of land have been degraded by human activities in semiarid and arid regions of the world and now need to be revegetated to control erosion and restore biomass production. Hillslopes in more humid regions have suffered similar degradation and need a dense vegetative cover to control accelerated runoff, erosion and downslope flash flooding and sedimentation. However, low-cost methods that work efficiently have not been available to accomplish revegetation under such adverse conditions on a broad scale.

To undergird the development of new techniques for restoring vegetation on degraded drylands and hillslopes, the important factors affecting rainwater infiltration were reviewed in the literature and then extensive infiltration studies were conducted from 1960 to 1976 under a wide range of climatic, edaphic, and vegetal conditions ( Dixon, 1975; Dixon and Peterson, 1971 ). These studies led to the conclusion that 2 physical properties of the soil surface--microroughness and macroporosity--exert a controlling influence over infiltration into initially dry soils. Manipulation of these two properties provides a one to two order-of-magnitude control over this hydrologic property ( Dixon , 1977 ).

Degraded land typically possesses a smooth, sealed soil surface with low infiltration rates, whereas biomass productive land has a microrough and macroporous surface with high infiltration rates. The microrough, macroporous surface is able to rapidly exchange rainwater and displaced soil air across the air-earth interface, whereas this fluid exchange is greatly impeded by the smooth, sealed surface. Thus, the hydrologic key to runoff, erosion and sedimentation control was to convert the smooth, sealed surface of degraded land back into the rough, open condition to, in turn, greatly increase water infiltration. And the key to low-cost revegetation was to develop an efficient mechanical technique for restoring stabile surface microroughness and macroporosity. Conventional tillage and planting implements can roughen and open the soil surface, but greatly destabilize it in the process. Typically these implements dig into, loosen, and invert surface soil covering some or all of the aboveground plant material. Such freshly-tilled loose surfaces smooth and seal rapidly under the impacting raindrops of intense rainfall and soon collapse like a "house of cards" squeezing out the macroporosity produced by tillage.

Using the new infiltration information, a tillage concept called land imprinting was developed ( Dixon, 1980; Dixon and Simanton, 1977 ), which then was implemented by the development of a series of soil surface imprinting devices beginning in 1976 and continuing to the present time. Unlike conventional implements, land imprinters do not dig into, loosen, and invert the surface soil, covering plant materials in the process. Instead they impress and emboss smooth-walled V-shaped furrows in the soil surface, mulching and partially imbedding any aboveground plant material that is available. The resulting waffled surface is relatively stabile and can rapidly infiltrate rainwater essentially where it falls. The V-shaped imprints funnel rainwater, seed, plant litter and splashed soil together where these resources can work in concert to germinate seeds and establish seedlings.

DESIGNS

A wide range of imprinting devices has been designed, fabricated and tested under a variety of field conditions. Early imprinters, many of which were fabricated at a U.S.D.A. field shop in Tombstone , Arizona , were massive steel rollers 1.0 to 1.5 m (3.3 to 4.0 ft) in diameter with complex patterns of angular imprinting teeth welded to the outer circumference ( U.S. Forest Service, 1980 ). These heavily weighted rollers produced corresponding soil imprint patterns when towed across the landscape with a crawler tractor. They were designed specifically to restore perennial grasses to desert and semidesert rangeland from which such vegetation had been eliminated by more than a century of cattle grazing. They were designed to interseed this missing component into the existing ecosystem with as little disturbance as possible. These imprinters were heavy enough to chew aboveground vegetation, including woody shrubs, into a soil-moisture conserving mulch which was partially imbedded in the angular faces of the soil imprint by the imprinting action. The large-diameter rollers easily rolled over large rocks and boulders and across deep gulleys, however they required a moderate-sized tractor for towing and were difficult to transport between imprinting sites.

Imprinters, designed and fabricated since 1985, have much smaller rollers ranging in diameter from 30.5 to 61.0 cm (12 to 24 in) ( Dixon and Carr,1991 ). These are cheaper to fabricate, easier to transport, and still make an adequate imprint. They also have greatly simplified tooth patterns. Typical cross-sectional roller geometries are square with four 90 ° points (the corners) and eight-pointed stars with either 90 ° or 45 ° points. These geometries are essentially the same as patchwork-quilt patterns referred to as tumbling blocks and rolling stars. The square or cube design is literally a case of reinventing the square wheel.

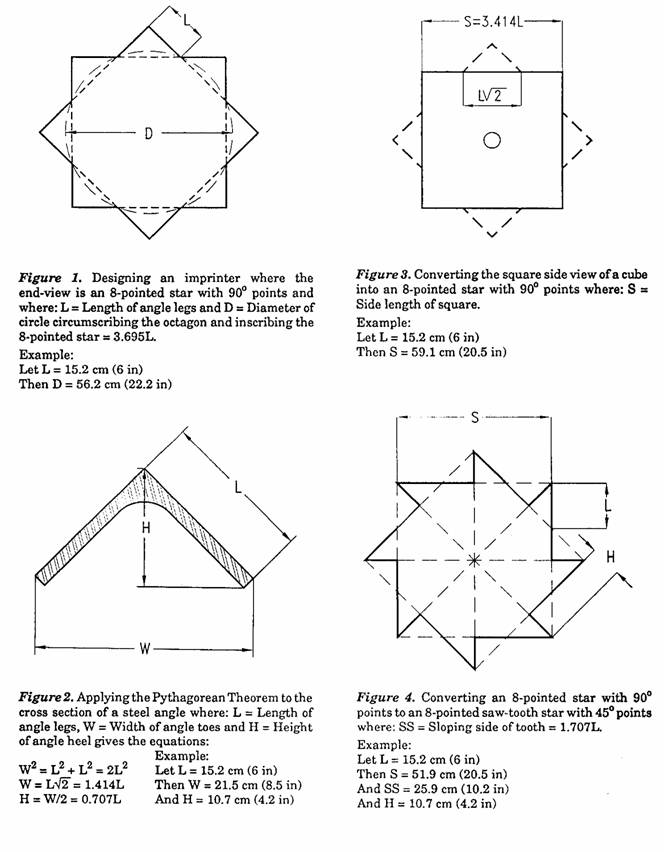

Designing an imprinting roller usually begins with the structural steel angle to be used for fabricating the teeth. Typically, steel angle which is 1.3 cm (0.5 in) thick with 15.2-cm legs (6-in legs) is cut into 25.4-cm (10-in) lengths. These teeth are then welded to the surface of a 61.0-cm (24-in) diameter steel pipe in a series of 8-pointed star rings (Fig. 1). The rings are spaced 5.1 cm (2 in) apart with the points of adjacent stars staggered with respect to each other ( Dixon , 1992a ). Modifications in this basic design are needed when the starting point is a steel cylinder either larger or smaller than 61.0 cm (24 in) or when the roller core is square instead of circular.

Roller design relies heavily upon the familiar Pythagorean Theorem which states: The square of the hypotenuse of a right triangle equals the sum of the squares of the other two sides. This theorem applies to the cross section of the steel angle used for teeth which becomes an isosceles right triangle when an imaginary line is drawn between the leg tips or the toes of the angle (Fig. 2). The discussion which follows will show how 42 - of the Pythagorean Theorem is used repeatedly in the design of several basic types of imprinting rollers.

Cube Types

The cube-type is the simplest design for imprinting rollers producing an imprinting pattern identical to the patch-work quilt pattern appropriately called tumbling blocks. Two or more steel cubes with an axle housing running through their centers are fabricated from steel plate. These cubes are then slipped onto an axle and fastened together with corners staggered. The end-view of the imprinting roller is an 8-pointed star with the first and second cubes on the axle each providing four, 90 ° points. Each cube can be converted to an 8-pointed star with 90 ° points by welding steel angles centered on each side of the cube (Fig 3.). The intrinsic advantage of the 8-pointed stars having 90 ° points is that minimal weight is required for tooth penetration because only one tooth contacts the soil at each 45 degrees of roller rotation.

Another variation of the cube-type roller is the saw-tooth star with 90 ° points which is created by removing one half of each 90 ° point of the 8-pointed star (Fig. 4). Except for the central axle housing, this roller is fabricated entirely from square, rectangular and triangular (right angle isosceles) steel plates. Another version of the saw-tooth roller is covered in the next section of this paper.

Cylindrical Types

Another type of imprinting roller has a cylindrical core to which angles are welded to form 8-pointed stars with 90 ° , 45 ° saw-tooth, and 45 ° symmetrical tooth points. The cylindrical roller with the 8-pointed stars having 90 ° points was mentioned previously (Fig. 1), but now it will be discussed in more detail. Again using the Pythagorean Theorem, the radius (R) and diameter (D) for the core of the 90 ° star rings is determined by the equations:

R 2 =[(2L + Lv2)/2] 2 +(Lv2/2) 2 =3.414L 2 R = 1.848L

D = 3.695L.

In practice a slightly larger diameter is selected to allow some space between adjacent legs for welding them to the surface of the cylinder. As an example, when L =15.2 cm (6 in), D = 56.2 cm (22.2 in). Thus, a diameter such as 61.0 cm (24 in) would be appropriate because this is a standard pipe size in United States (Fig. 5).

Figure 5. Typical imprinting roller-and-axle assembly including pillow

block bearings wherein the core is a standard 61.0-cm (24-in) steel pipe.

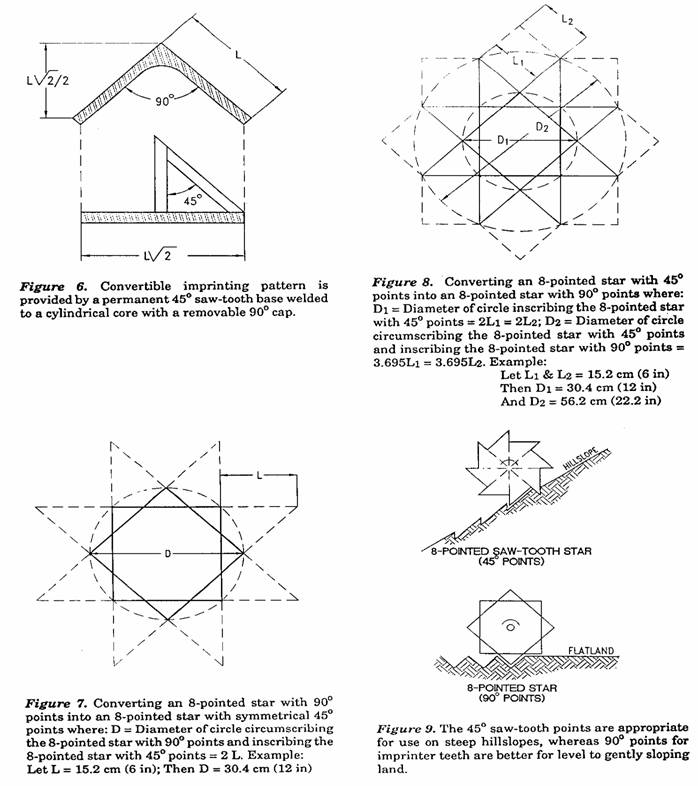

The 45 ° saw-tooth points may be fabricated by welding rectangular base plates to the cylindrical core. The 45 ° saw teeth are then welded permanently to one side of these base plates.(Fig. 6) Such teeth can be capped with 90 ° teeth held in place by temporary welds to make the imprinter more versatile.

Geometrically, converting an 8-pointed star with 90 ° points as shown in Fig 1. to an 8-pointed star with symmetrical 45 ° points is quite simple (Fig. 7). To make this roller, the diameter (D) of the core cylinder should be equal to twice the length (L) of the steel angle leg or D = 2L. However in this case, the angle teeth are turned upside-down and the heel of the angle is welded to the core with the legs angling outward to form the 45 ° points. Tips of the legs are welded together and then sharpened to aid in soil penetration. Welding a small steel angle to the leg tips can expedite the sharpening process. In cross section this roller is identical to the patch-work quilt design appropriately called "rolling star."

The 45 ° points of this roller can be easily converted to 90 ° by attaching another set of angular teeth of the same size as those used to create the 45 ° points ( Fig. 8 ). The leg tips of the 90 ° angles are welded temporarily to the 45 ° points. The core diameter of the roller with the 90 ° points is 1.85 times larger than the roller with the 45 ° points.

The rolling imprinters with convertible teeth are especially versatile because the 90 ° points generally work best on level to gently sloping land, whereas the 45 ° points are superior for use on steep slopes (Fig. 9). In general the 45 ° imprint is superior for large-seeded species and the 90 ° imprint is best for small seeds.

The designs of rolling imprinters, previously discussed, are just a few of the basic types that can be fabricated in a shop equipped with only a cutting torch and a stick welder. These basic designs point to an infinite number of variations and combination designs. For example imprinting teeth with 90 ° points and 45 ° sides are relatively easy to fabricate and have many uses. Another useful variation would be to alternate between 90 ° and 45 ° points on the same roller to provide greater diversity of seedbed geometries, as could be easily done with the tooth cap shown in Fig. 6.

Imprinting rollers can be fabricated in almost any size ranging from those requiring the power of large crawler tractors down to small rollers that can be operated by a garden tractor or hand-pushed. Angle leg length (L) can vary from 5.1(2 in) to 25.4 cm (10 in) although the 15.2-cm (6 in) size is typical of the imprinters designed, fabricated and used heretofore.

Other Types

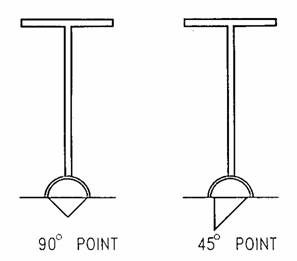

Hand- and foot-operated imprinters of several different designs have been fabricated and tested. The hand imprinter is operated in a manner somewhat similar to garden tools such as forks, spades and shovels ( Dixon , 1982 ). Typically it has a single angular imprinting tooth with either a 45 ° or 90 ° tip which is forced into the soil through the combined forces applied by the hands on a T-handle and one foot in a D-shaped stirrup ( Fig. 10 ).

The foot imprinters are toothed flat plates which are strapped to each foot which, in turn, imprint the soil as the operator walks. Both the hand- and foot-operated imprinters work best on soil softened by water, tillage, or high organic matter content.

Figure 10. Hand-operated imprinters with 45 ° and 90 ° tooth points for use in

small land areas which are relatively steep and level, respectively.Weighting

As with many types of tillage tools, rolling imprinters often have insufficient basic weight to obtain adequate soil penetration. Thus, additional weight must be added to the core of the imprinting roller. Alternatives include filling the core with concrete, gravel, sand, soil, soil slurry and water with the last two being drainable for lighter transport. More weight can be balanced over the roller axle by attaching tanks or boxes to the tow frame. To allow room for a centrally mounted seeder, the weight is usually divided equally between the front and rear sides of the rectangular tow frame by mounting either tanks for water or steel boxes for solid weighting materials ( Dixon , 1992a ). Solid materials that have been used include soil, sand, gravel, bricks, concrete, and cast iron tractor weights. Imprinting pressures should range from 83 kPa (12 psi) for soft soils to 331 kPa (48 psi) for hard soils. To avoid excessive water with the last soil compaction no more weight should be used than that required to obtain a full-tooth imprint, which is attained when teeth penetrate the soil about halfway because of the embossing effect. At the halfway point the load bearing capacity of the soil or upward acting resistive force should just equal the downward acting imprinting force ( Dixon , 1992a) .

Attachments

Useful imprinter attachments include seeders and rippers. Both broadcast and drop seeders have been used to scatter seeds on the soil surface. Drop seeders distribute seed more uniformly and are less affected by wind and physical differences in seed such as size, shape, density, smoothness/roughness and appendages.

In general seeds are applied in front of the imprinting roller so that they become embedded in the faces of the imprint. This provides good seed-soil contact, some coverage and high and dry storage for some of the seed. Over time seed tends to move into imprint troughs under the forces of animal activity, wind, water and gravity. With each rain additional seed washes into the troughs, thus providing a number of opportunities for successful seed germination and seedling establishment. This is especially important because of the erratic rainfall of desert regions and the complex native seed mixes used in ecological restoration projects which possess a wide range of dormancies and germination requirements.

The most successful seeder has been a homemade drop-type with a flexible four-vane agitator mounted directly over the imprinting roller and driven by a rubber tire contacting the imprinting teeth. Seed is dropped directly on top of the roller, carried forward by the roller and embedded in the imprint. This seeding imprinter is quite trouble free as it has only two moving parts--the imprinting roller and the seed agitator ( Dixon , 1992a).

Ripping shanks have also been attached to the imprinter frame, just in front of the imprinting roller, to loosen extremely hard dry soils enough to obtain adequate penetration of imprinting teeth. This permits ripping, seeding and imprinting in rapid-fire sequence all in one operation. Where deep compaction has occurred by repeated heavy equipment traffic, deep ripping should be carried out initially with heavy duty equipment, however where soil hardness is superficial the imprinter-mounted ripping shanks can do an adequate job.

FUNCTIONS

Land imprinters can effect low cost revegetation in arid and semiarid regions because they are very simple machines that can efficiently perform six important water collection, concentration and conservation functions to make better use of limited precipitation in the germination of seeds and the establishment of seedlings. These functions are plant material mulching, soil firming, resource trapping, resource funneling, water infiltrating, and shielding of seedlings from the severe macroclimate.

Mulching

Imprinting teeth bite against the hard soil, chewing any aboveground plant material into a mulch which becomes embedded in the faces of the imprint. Pioneer/annual plant species (weeds) that typically colonize disturbed land areas make excellent mulch to conserve water to, in turn, help accelerate natural plant succession to perennial species. Imprinter mulching conserves soil moisture directly and indirectly in a number of ways. It suppresses or eliminates transpiration by killing aboveground growth of plants. Mulch suppresses surface evaporation of soil moisture by reducing the vapor pressure gradient at the soil surface. It stabilizes the water conserving imprints to permit them to function for a much longer period of time. Mulch cools the soil and shades small seedlings to reduce transpiration. It feeds invertebrate animals that enhance water infiltration through their burrowing activities. On decomposition or mineralization, mulch builds soil structure to increase infiltration and soil-water holding capacity. Additionally, the mulch builds topsoil by adding organic matter and plant nutrients.

Firming

The soil firming function or process of land imprinting occurs simultaneously with the mulching process. Firming enhances capillary flow of deep soil moisture up to the seedbed for rewetting of the seeds at least at dawn on several successive days following moderate rainfall. Seeds of desert adapted species are engineered by evolution to germinate during such periodic wetting and rewetting. Firming also improves seed-soil contact which likewise enhances capillary water flow into the seed. Firming increases surface stability to maintain the other water conserving functions of imprints for a longer period of time. Firming retains more moisture in the seedbed itself to aid germination. It embeds plant litter and other plant materials to further stabilize the imprint. Embedding of this material speeds decomposition and thus enrichment of the surface soil with organic matter and plant nutrients.

Firming promotes cracking along the bottom of the imprint trough which, in turn, enhances infiltration and seedling emergence through a crust. In fact deleterious soil crusting is seldom encountered in connection with land imprinting because of controlled cracking, litter trapping, and daily capillary rewetting of the seedbed. One further note , capillary rewetting after drilling or other conventional seeding methods occurs for a much shorter period of time relative to imprinting. This is perhaps the major reason for a much lower success rate for drill seeding compared with imprinter seeding.

Trapping

Through the process of imprinting, discontinuous V-shaped pockets are formed, which are very effective in trapping or collecting resources essential for germinating seeds and establishing seedlings. Conventional methods such as seed drills create continuous furrows that tend to bleed resources downslope during rainfall of sufficient intensity and duration to produce runoff. Such resources are eventually piled up at the bottom of the slope as sediments. Imprinting also produces V-shaped troughs on the contour during up-and-down slope operation, whereas conventional planters produce furrows in the direction of travel. Just as soon as the angular imprint is made the trapping process begins. Imprints trap airborne resources such as seed, rainwater, snow, spores, and plant litter. They also trap splash- eroded soil. By ponding rainwater in place, imprints not only increase the rate, but also the duration of the infiltration process. Imprinter design should stress the importance of this trapping or collecting process in the revegetation of degraded hillslopes. Imprinted V-troughs should be short and staggered with adequate damming in between to prevent rainwater from taking a zig-zag pathway downslope.

By safely ponding rainwater and increasing infiltration, imprints are very effective in erosion and sedimentation control. They also provide stabile surface roughness for effective wind erosion control.

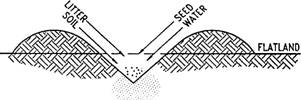

Funneling

Closely related to the trapping function is the funneling action of the V-shaped imprints ( Dixon , 1990 ). Trapping involves the holding of resources in place against the forces of wind, water and gravity, whereas funneling entails the gravitational concentration of these resources at the bottom of the V-trough where they are in position to work in concert to germinate seeds and establish seedlings ( Fig. 11 ). This funneling action is quite efficient because the V-furrows are smooth-walled and small-pored due to the firming function previously discussed. The great steepness of the side slopes (45 ° or 100%) also increases the funneling efficiency. Funneling of rainwater infiltrates it deeply and directly below the seeds where it can readily return by capillary flow to germinate seeds and then feed the seedling roots as they grow downward. The concentration and resultant deep penetration of rainwater also helps to conserve soil moisture as it is less susceptible to loss by surface evaporation as compared with superficial moisture.

Figure 11 . Imprints funnel resources together in the bottom of V-shaped imprints where

these resources are concentrated to germinate seeds and establish seedlings.

Infiltrating

The conception of land imprinting grew out of infiltration research which showed that land degradation smoothes and seals the soil surface, thereby reducing infiltration to as little and 1/10 to 1/100 of the non-degraded rough-open soil surface. Thus, imprinting a smooth-sealed surface converts it into the rough-open condition to increase infiltration rates by a factor of ten or more. Rainfall simulator trials showed that sealed surfaces often infiltrate only about 1 cm during the first hour compared with about 10 cm for the rough-open surface. Ten cm in one hour is the maximum 100-year rainfall for most of interior United States having a continental climate ( Dixon and Simanton, 1979 ). Thus runoff and erosion ceases to be much of a problem for storms of greater frequency since most, if not all, of the rainfall will infiltrate the rough-open surface.

The infiltrating function of imprints is closely related to the funneling function. High infiltration results when rainwater is rapidly funneled into the soil via the V-shaped imprinted depressions and the soil air that is displaced by the infiltrating water is funneled out of the soil just as rapidly via the V-shaped imprinted ridges which are in essence inverted funnels. It is this unimpeded simultaneous exchange of these two fluids across the air-earth interface that accounts for the rapid infiltration of rainwater by the microrough, macroporous surface. In contrast the smooth, sealed surface of degraded land greatly impedes this exchange ( Dixon , 1990 ).

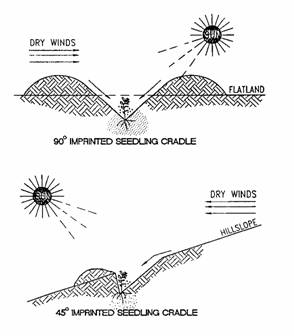

90 ° IMPRINTED SEEDBED

Figure 12. Imprints make good seedling cradles to help seedlings establish themselves

by shielding them from the desiccating winds and intense sunlight of desert regions.Shielding

The foregoing functions of imprints account collectively for the superior seedbeds created by imprinting degraded arid and semiarid lands. Once seed germination has occurred, then the seedling shielding function comes into play. The V-shaped imprints shield tender young seedlings from the stressing macroclimate, especially the desiccating winds and intense sunlight (Fig. 12 ). Any mulching that occurred during imprinting also helps to moderate the microclimate to which small seedlings are exposed. Air-borne plant litter is trapped and funneled by the imprints to where it can help shield seedlings. Thus, imprinting produces relatively safe seedling cradles. By the time the seedling grows up out of the V-shaped imprints into the harsh macroclimate above, its roots . have penetrated deeply into the moist soil below

The good supply of deep soil moisture that small seedlings can readily tap is the net effect of the imprinting functions previously discussed. This soil moisture also increases the humidity and moderates daily temperature fluctuations of the seedling cradle. Thus, the shielded seedling grows rapidly and is well on its way to becoming established when it emerges from the seedling cradle.

USES

Imprinters are designed to accomplish such tasks as desertification reversal, land revegetation, rehabilitation, regeneration, renovation and reclamation; infiltration, runoff, erosion and sedimentation control; and finally ecological restoration. These tasks are all related in that human activities recently or historically have caused land disturbances resulting in land degradation. Also land amelioration almost always involves the reestablishment of vegetation which, in turn, usually means seeding of one or more species especially where land areas are too large for transplanting of seedlings. Seedbed and seedling cradle design is especially critical where the water resource is limited such as in arid and semiarid lands and in steeply sloping land. These are the land areas for which land imprinters were, and are being, designed to provide a means for low-cost revegetation through efficient use of scarce and unpredictable precipitation.

Since 1976, rolling land imprinters have been used to restore vegetation on tens of thousand of hectares of rangeland in the Sonoran Desert region of southern Arizona , USA which was degraded by cattle grazing during the past century. Imprinters have also revegetated land degraded by cotton farming, nuclear power plant installation, aqueduct construction, military activities, airport runway construction, urban developments and landfills. Hand and foot imprinters have been used primarily in residential landscaping.

FUTURE OUTLOOK

Looking ahead to future applications of imprinting technology, we expect uses to include revegetation of areas in the Colorado and Mojave Deserts of California --arid regions with only a winter rainy season compared with two rainy seasons in the Sonoran Desert ( Dixon , 1993). Future uses are also expected to include agricultural cropping of dry and irrigated lands. Current imprinter designs discussed herein should be well suited to restoring marginal croplands to prairie in the western Great Plains region. Similarly, these designs should require little change for seeding of wheat and other small grains in the Great Plains and elsewhere. Ripping, seeding and imprinting directly into the wheat stubble of last years crop should provide a high degree of soil and water conservation. Successful tests have already been conducted for imprinter seeding of both wheat and alfalfa; and the interseeding of legumes into bluegrass pasture in the Corn Belt . Irrigated pasture of both warm and cool species has been established by imprinting. Current imprinter designs and equipment should adapt readily to the establishment of cover, nurse, mulch, and green manure crops in various conservation rotations.

Imprinting has potential for solid-stand planting of major row crops such as grain sorghum, soybeans and corn. If successful, the solid stand practice would represent a major advance in the conservation culture of these crops because cultivated rows tend to route rainwater and eroded soil rapidly downslope during intense rainfall.

The solution to controlling runoff, erosion and sedimentation in agricultural lands has always been the maintenance of a dense groundcover of vegetation or plant residues for 365 days each year. This ideal can be approximated by crop rotations which include perennial grasses and legumes, no-till solid-stand planting of annual crops and liberal use of cover, nurse, mulch and green manure crops. By keeping the soil well-covered at all times and using a no-till method such as imprinting for seeding and planting crops, the long sought-after-goal of holding topsoil and rainwater in place can perhaps be achieved. This is the best way to rebuild a deep and productive topsoil. Imprinters are uniquely capable of planting or seeding through a heavy mulch of plant residues without leaving continuous furrows or marks of any kind for water to follow downslope.

Land imprinting is expected to find an increasing number of uses in the future because it works well in the revegetation of degraded land and its cost is relatively low. Globally, the amount of degraded land is growing rapidly and the need for returning this land to productive use is increasing exponentially, driven by a similar growth in world population. With a rising concern for environmental degradation, these degraded lands need to be made productive again in the most benign way possible. Productive, not just to directly satisfy human needs, but also to meet the needs of endangered natural ecosystems of plants and animals that are the very foundation of all life on earth. Land imprinting has already been used in two large scale projects directed to seeding complex mixes of native plant species to, in turn, accelerate natural plant succession rapidly toward a productive and hopefully somewhat natural ecosystem ( Dixon and Carr, 1993 ).

By making good use of onsite resources, land imprinting should minimize the need for massive outside inputs from the petrochemical industry. The reasons for imprinting's success in revegetation were detailed previously in the section entitled "Functions"; however, in summary imprinters are effective because they produce superior and more durable seedbeds and seedling cradles. Reasons for the relatively low cost are briefly noted here. First, and perhaps most importantly, the higher success of imprinter seeding, relative to conventional methods such as drill seeding, greatly reduces the cost because the need for reseeding seldom occurs. The success rate of imprinting for establishing vegetation in the arid and semiarid region of southwestern United States has been about 90% compared with only about 10% for drilling. In fact the extremely low success of conventional methods was the justification used by the senior author for spending U.S.D.A. research funds in the development of the land imprinting approach beginning in 1976 (Pratt, 1983).

Imprinters are very simple and durable machines having only a single moving part, or two if equipped with a seeder. This means lower (relative to seed drills) initial cost, lower maintenance cost, less down-time and lower replacement cost because of longer life. Fortunately, imprinting teeth are self-sharpening as they wear concave on the leading side just above the imprinting point or cutting edge. When this concave wear extends about halfway through the angular tooth, the imprinting roller is reversed end-for-end to initiate concave wear on what was the trailing side of the teeth, thereby essentially doubling the life of the imprinting teeth. When the teeth are worn on both sides, they can be hard-surfaced or capped with new steel angle teeth.

About the only other repair we have experienced is replacement of the pillow block bearings used on the roller axle. The need for this repair can be minimized by using heavy duty bearings. Where repeated shock is encountered such as hitting and rolling over large boulders and stumps, we suggest using a cast-steel bearing housing instead of cast iron ( Dixon , 1992b ).

In the more humid regions where effective revegetation methods are already available, the cost advantage of imprinting would not be as great. Advantages such as better control of erosion and sedimentation, especially on hillslopes, are difficult to evaluate because economic and ecologic benefits tend to be long range.

REFERENCES

Dixon , R.M.1975. "Infiltration Control through Soil Surface Management." Proceedings Symposium on Watershed Management, American Society Civil Engineers and Utah State University . p. 543-567.

Dixon , R.M. 1977. "Air-Earth Interface Concept for Wide-Range Control of Infiltration." Annual Meeting American Society Agricultural Engineers. Raleigh , North Carolina . Paper No. 70-2062, 33 pgs.

Dixon , R.M. 1980. Land Imprinter. U.S. Patent No. 4185655, U.S. Patent Office, Washington D.C.

Dixon , R.M. 1982. "The Hand Imprinter." Arid. Lands Newsletter, No. 17, Office of Arid Lands Studies, University of Arizona, Tucson. p. 14-15.

Dixon , R.M. 1990. "Air-Earth Interface Model for Ecosystem Restoration and Maintenance." Proceedings Society for Ecological Restoration. Madison , Wisconsin . p. 172-181.

Dixon , R.M. 1992a. The Landfill Imprinter. Design, Operation and Maintenance. Imprinting Foundation, 1231 E. Big Rock Road , Tucson , Arizona . 17 pgs.

Dixon , R.M. 1992b. Specifications for Landfill Seeding Imprinter. Imprinting Foundation, 1231 E. Big Rock Road , Tucson , Arizona 4 pgs.

Dixon , R.M. 1993. Revegetation of OHV Disturbed Land in the Mojave and Colorado Deserts of California . Imprinting Foundation, 1231 E. Big Rock Road , Tucson , Arizona . 5 pgs.

Dixon , R.M. and AB. Carr. 1991. " Designing Land Imprinters for Ecological Restoration." Agronomy Abstracts. American Society ofAgronomy, Madison , Wisconsin . p. 329.

Dixon , R.M. and AB. Carr. 1993. "Recent Revegetation Projects in Southern Arizona Using Land Imprinting." Abstracts for Fifth Annual Conference Society for Ecological Restoration, Irvine , California . p. 35.

Dixon , R.M. and AE. Peterson. 1971. "Water Infiltration Control: A Channel System Concept." Soil Science Society of America Proceedings 35: 968-973.

Dixon , R.M. and J.R. Simanton. 1977. "Land Imprinter for Revegetation of Barren Land Areas through Infiltration Control." Proceedings American Water Resources Association and Arizona Academy of Science 7: 79-88.

Dixon , R.M. and J.R. Simanton. 1979. Water Infiltration Processes and Air-Earth Interface Conditions. Surface and Subsurface Hydrology, H.J. Morel-Seytoux, J.D. Salas, T.G. Sanders, R.E. Smith (Eds), Water Resources Publication, Fort Collins, Colorado. p. 314-330.

Pratt, Marianna. 1983. "Land Imprinting for Lasting Impressions." Agricultural Engineering, No. 9, 64: 8-10.

U.S. Forest Service. 1980. Land Imprinter. Revegetation Equipment Catalog. Revegetation Rehabilitation and Equipment Workshop. Forest Service, U.S.D.A Equipment Development Center , Fort Missoula , Montana . p. 79-80.The Imprinting Foundation

1616 E. Lind Road

Tucson, AZ 85719Close Window to Return to List

If you entered our site on this page, click on Logo below to go to the Imprinting Foundation for more Information